Description

Calpeda MXV-B Vertical Multi Stage Pump

Construction

Vertical multi-stage close coupled pumps with suction and delivery connections of the same diameter and arranged along the same axis (in-line).

All parts that come into contact with the liquid, including wet- end covers , are in chrome-nickel stainless steel with corrosion-resistant bearing sleeves lubricated by the pumped liquid.

Applications

For water supply systems .

For clean non-explosive liquids, without solid, filamentary or abrasive matter and non- aggressive for stainless steel (with adaptation of sealing materials on request).

A universal pump for civil and industrial use, for pressure- boosting systems , fire-extinguishing systems , high-pressure washing plant s, irrigation, agricultural uses and sport installations .

Operating conditions

Temperature of liquid: from - 15° C to + 90°C.

Operating environment temperature: up to 40°C.

Maximum permissible pressure in pump casing: 16 bar .

Motor

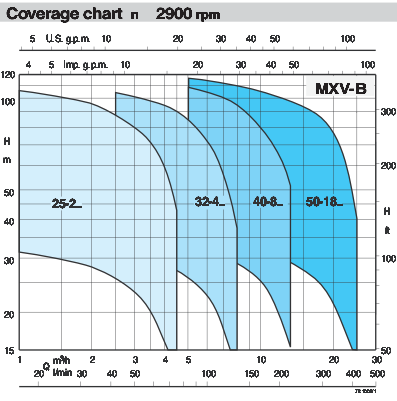

2 - pole induction motor, 50Hz (n=2900rpm).

MXV-B : three-phase 230/400V ± 10% up to 3kW;

MXV-BM : single-phase 230V ± 10%;

With thermal protector.

Capacitor inside the terminal box.

Insulation class F.

Protection IP54 .

Classification scheme IE2 for three-phase motors .

Constructed in accordance with: EN60034-1, EN60034-30.

EN60335-1,EN60335-2-41.

Features

- Wider Range of Application

- All parts that come into contact with the liquid, including wet- end cover s, are in chrome- nickel stainless steel.

- With corrosion-resistant seal rings and guide ring.

- Low Cost Installation

- Vertical construction with reduced pump height for installation in small spaces.

- In- line connections to simplify the piping layout with the possibility of inserting the pump in straight pipe- lines .

- Disassembly , inspection or cleaning of internal parts without removal of piping.

- Robust and Reliable

- The suction and discharge nozzles arranged in-line absorb the forces of the piping on the pump without the creation of distorting loads causing local friction and early wears.

- The lantern brackets compact and robust design maintains a sure alignment between rotating and fixed parts , reducing vibration.

- The upper cover design of events entrapment of air around the mechanical seal.

- Low-Noise Operation

- The water filled shroud around the stages and thick external walls, work together for low-noise operation.

Calpeda MXV-B PDF Brochure Download