Lowara Pumps

Lowara 1SV Series Vertical Multistage Pumps

- Availability:

- In Stock

- Shipping:

- Free Shipping

Description

Lowara 1SV Series Vertical Multistage Pump

| PDF Download |

| Lowara SV Leaflet |

e-SV

1SV Pump PerformanceStainless steel vertical multi-stage pumps.

Why “e”-SV? “e” stands for the ultimate in energy efficiency, easy installation and economical operation - a new generation of vertical, multi-stage pumps that deliver outstanding performance and reliability.

Developed based on intensive research into user needs, the new e-SV pumps are designed to extend up-time and help reduce life cycle costs in a wide variety of demanding applications.

Stainless Steel Vertical Multi-stage Pumps

Multistage Pumps - e-SV

Highly reliable and technologically advanced multipurpose pump capable of satisfying the needs of a wide variety of users. Many different construction designs are available, with models featuring 1-3-5-10-15-22-33-46-66-92-125 m3/h nominal capacities.

All >= 0.75kW are equipped with IE2 standard motors.

New design features:

Balanced mechanical seal replaceable without need for pump disassembling (for 10-15-22SV>=5,5kW, 33-46-66-92-125SV)

"O" Ring seat design to allow for simple outer sleeve disassembly

Floating for self alignment replaceable diffuser wear ring (PPS Glass filled tecnopolymer to withstand chemically corrosive, mechanically aggressive and high temperature liquids)

Reduced impeller axial thrust for longer standard motor bearing life (17,500h)

Hard Material Intermediate bush bearing (Tungsten Carbide/Silicon Carbide) to improve life and ability to withstand heavy duty applications, like boiler feeding

High temperature seal option (150°C max) with low NPSH design, high pressure design (up to 40 Bar), and passivated & electro-polished version are available upon request.

Further unique features of the e-SV include the integration of performance diagnostic devices such as the i-Alert™ vibration monitor and Dry Run sensor. i-Alert™ is provided as standard on ≥7.5kW, and as an accessory on all other models. The Dry Run sensor is available as an accessory for all models.

Specifications

Delivery: up to 160 m³/h (125SV Series)

Head: up to 330 m (46SV)

Power supply: both single and three-phase 50 and 60 Hz

Power: from 0.37 kW up to 55 kW

Maximum operating pressure: 40 bar

Temperature of pumped liquid: from -30 °C to 120 °C

Applications

Commercial-Water

Commercial-Treatment

Commercial-Fire/Fighting

Light Industry-Water

Light Industry-Treatment

Agriculture-Irrigation

Golf/Turf-Irrigation

| 1SV Series | Hydraulic Performance Table at 50 Hz 2 Poles | |||||||||

| New Pump Model | kW | HP | l/min | 0 | 12 | 20 | 25 | 30 | 35 | 40 |

| m3/h | 0 | 0,7 | 1,2 | 1,5 | 1,8 | 2,1 | 2,4 | |||

| 1SV02 | 0,37 | 0,5 | Head metres | 12,2 | 12,2 | 11,5 | 10,7 | 9,5 | 7,9 | 6,0 |

| 1SV03 | 0,37 | 0,5 | 18,0 | 18,0 | 17,0 | 15,7 | 13,8 | 11,4 | 8,4 | |

| 1SV04 | 0,37 | 0,5 | 23,7 | 23,5 | 22,1 | 20,4 | 17,9 | 14,6 | 10,6 | |

| 1SV05 | 0,37 | 0,5 | 29,3 | 28,9 | 27,0 | 24,8 | 21,6 | 17,4 | 12,5 | |

| 1SV06 | 0,37 | 0,5 | 34,8 | 34,2 | 31,7 | 28,9 | 25,0 | 20,0 | 14,0 | |

| 1SV07 | 0,37 | 0,5 | 40,2 | 39,2 | 36,1 | 32,7 | 28,1 | 22,2 | 15,2 | |

| 1SV08 | 0,55 | 0,75 | 48,1 | 47,9 | 45,2 | 41,8 | 36,8 | 30,4 | 22,4 | |

| 1SV09 | 0,55 | 0,75 | 53,7 | 53,4 | 50,4 | 46,4 | 40,8 | 33,5 | 24,6 | |

| 1SV10 | 0,55 | 0,75 | 59,4 | 59,0 | 55,5 | 51,0 | 44,7 | 36,6 | 26,6 | |

| 1SV11 | 0,55 | 0,75 | 65,1 | 64,5 | 60,4 | 55,5 | 48,5 | 39,5 | 28,5 | |

| 1SV12 | 0,75 | 1 | 73,3 | 73,1 | 69,3 | 64,3 | 57,1 | 47,6 | 35,7 | |

| 1SV13 | 0,75 | 1 | 79,2 | 78,9 | 74,8 | 69,4 | 61,6 | 51,2 | 38,2 | |

| 1SV15 | 0,75 | 1 | 90,9 | 90,5 | 85,6 | 79,3 | 70,1 | 58,1 | 43,1 | |

| 1SV17 | 1,1 | 1,5 | 105,2 | 104,9 | 100,0 | 93,1 | 82,6 | 68,6 | 51,2 | |

| 1SV19 | 1,1 | 1,5 | 117,0 | 116,7 | 111,0 | 103,2 | 91,5 | 75,8 | 56,3 | |

| 1SV22 | 1,1 | 1,5 | 134,6 | 134,1 | 127,4 | 118,1 | 104,4 | 86,1 | 63,5 | |

| 1SV25 | 1,5 | 2 | 152,6 | 152,4 | 145,5 | 135,4 | 120,0 | 99,1 | 72,7 | |

| 1SV27 | 1,5 | 2 | 164,3 | 164,0 | 156,4 | 145,4 | 128,8 | 106,1 | 77,5 | |

| 1SV30 | 1,5 | 2 | 181,7 | 181,3 | 172,6 | 160,1 | 141,2 | 115,7 | 83,9 | |

| 1SV32 | 2,2 | 3 | 197,2 | 197,1 | 188,4 | 175,8 | 156,5 | 130,0 | 96,3 | |

| 1SV34 | 2,2 | 3 | 209,2 | 208,9 | 199,8 | 186,3 | 165,5 | 137,1 | 101,2 | |

| 1SV37 | 2,2 | 3 | 225,9 | 224,9 | 216,1 | 201,9 | 179,3 | 148,1 | 108,7 | |

Please Note: The replacement table guide above is based upon the equivalent duty at the best efficiency point on the operating curve, for other specific duties or application types a different selection maybe more appropriate - please contact our sales office.

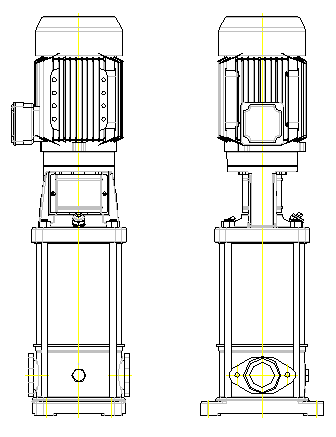

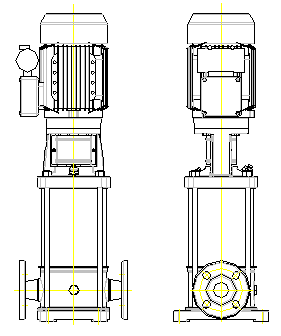

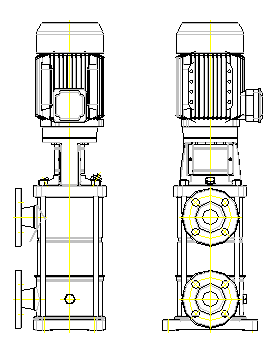

| There are three versions of flange configuration available. | ||

|

|

|

| T: AISI 304, in-line oval flanges | F: AISI 304, in-line round flanges | R: AISI 304, discharge port above suction, round flanges |

| Version T oval flanges includes counter flanges, for round flanges (versions F & R, counter flanges will need to be ordered separately) Galvanised or Stainless Steel | ||

| Version T Oval flanges will be sent as standard, if you require round flange Version F or R put note in checkout or order counter flanges. if required |

||